Introduction

Live training for Lean and TPM practitioners

Seven-day certificate training for lean multipliers and TPM experts,

who take on a new role in the practical implementation of Lean.

Lean continues to be the foundation for many of the new challenges in our factories! But how can lean successes, once achieved, be sustainably established? And how can new and young employees be introduced to the tried-and-tested methods?

This training takes place in cooperation with three organizing companies. These companies have been developing successful multiplication and training concepts for over 20 years in a network with the best lean implementations in Germany, thus ensuring sustainability in their own plants. Looking over the fence and cross-company exchange is a decisive success factor here.

All modules take place live in factories in a practical setting

Start of training at Wieland-Werke AG in Villingen as an example of best practice (TPM Factory of the Year)

Based on the proven lean principles and tools

Diese Veranstaltung ist leider ausgebucht. Wir starten die nächste Runde am 25. März 2025. Weitere Informationen und Anmeldemöglichkeiten finden Sie hier ...

Fit for the role of lean multiplier in your factory?

Siebentägige, paxisnahe Ausbilung in drei Blöcken:

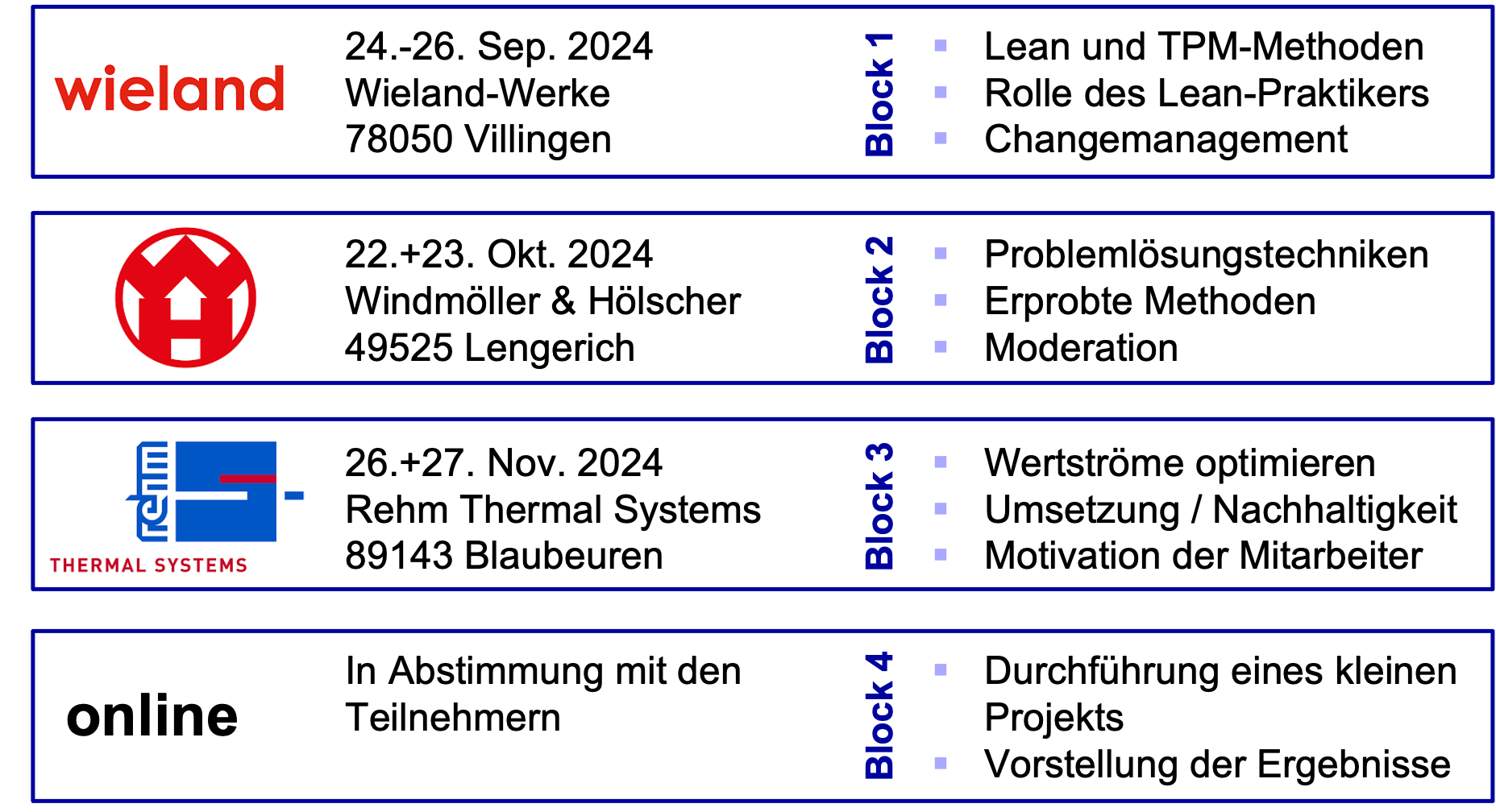

Dates:

Participation fee: 2,950 euros plus statutory VAT

Special features of this live training :

- The training was developed with a practical orientation in a group of successful TPM and lean companies and has been successfully implemented for over 10 years.

- Start of training at Wieland in Villingen, one of the best TPM factories.

- All modules take place live in companies, so that a direct link to practice is guaranteed.

- Lean method training is combined with training in application skills (moderation, problem-solving skills, social skills, etc.).

- Access to many best-practice examples.

- Option to implement your own project in parallel and present it in a digital degree.

Target group :

- Selected new multipliers, trainers and moderators

- Experienced practice experts who take on a new role in the CIP

- Future supporters of the improvement process

- prospective CIP coordinators and process facilitators, new project managers, Kaizen managers

In this 7-day training course you will learn :

- the basic lean methods and tools

- Understanding your role and your success factors as a multiplier

- Successfully plan, manage and secure improvements and workshops

- Successfully plan, manage and secure improvements and workshops

-

Safe handling of conflicts

- the foundations for ensuring sustainable results

Block 1 at Wieland-Werke AG:

Day 1 - 24.09.2024

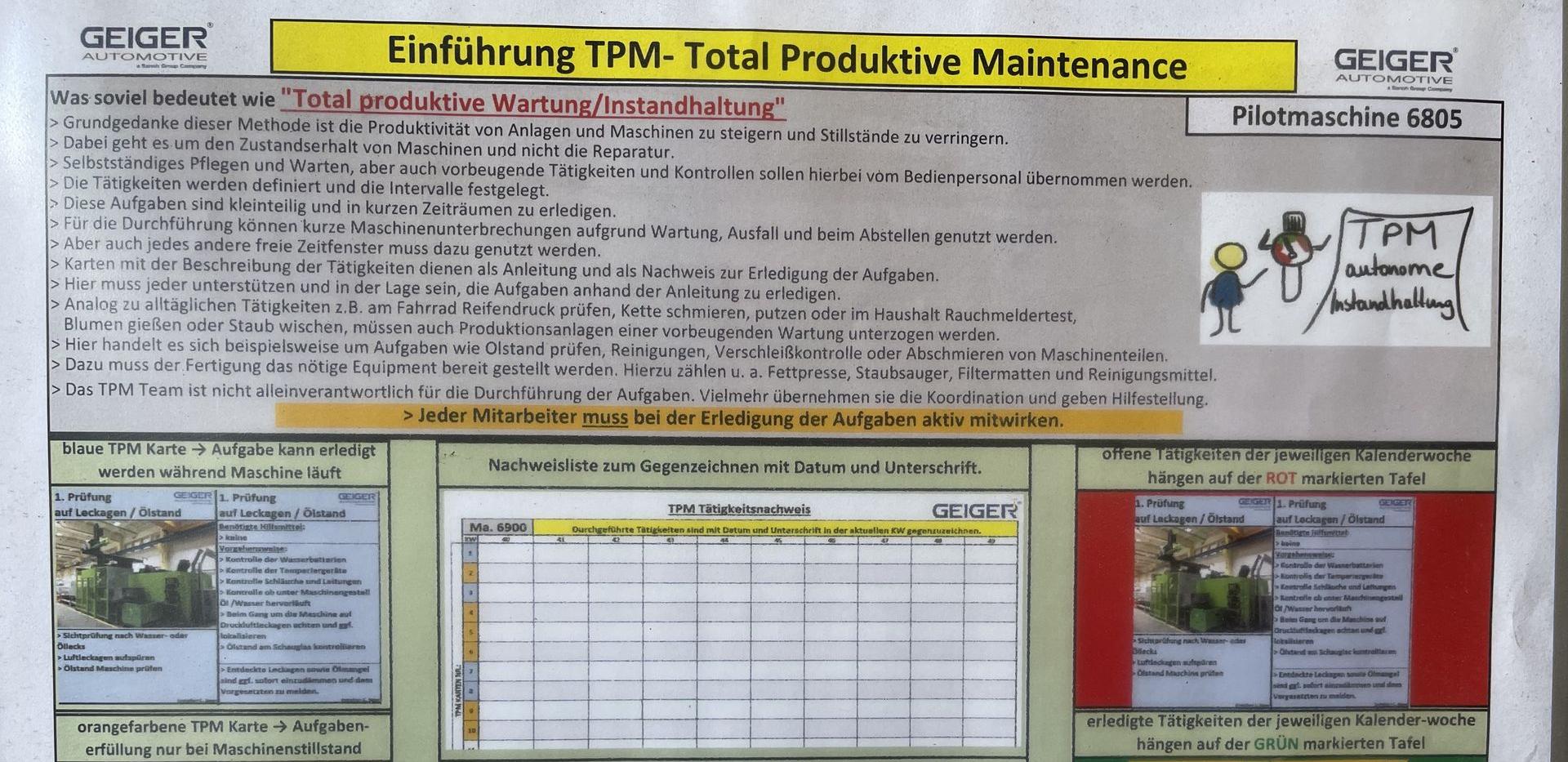

TPM at Wieland: Insights into practice with many live stations

- TPM level on systems

- OEE recording and optimization

- The role of maintenance as a partner

- Standards for optimization

- Shopfloor management

- Involving employees in the change process

- Development of a TPM / Lean system

- Understanding the lean principles

- The role of the lean practitioner

Day 2 - 25.09.2024

Overview of lean and TPM methods

- TPM pillar model

- Autonomous maintenance

- Planned maintenance

- Detecting and eliminating center of gravity losses

- 5S as a basis

Day 3- 26.09.2024

The role of the lean practitioner in the change process

- Recognize, learn and resolve blockages and resistance

- Accompanying change professionally as a change manager

- Successfully implementing CIP methods in the company

- Basics of agile project management and simple SCRUM tools

Block 2 bei WINDMÖLLER & HÖLSCHER KG

Tag 4 - 22.10.2024

Moderation and communication as a lean and TPM practitioner

- Basic principles of moderation

- Structure and preparation of a moderation and the role of the moderator

- Moderation techniques and rhetoric. Suggestions for small group moderation, rhetorical tips and tricks

- Procedure for a group meeting or workshop

Tag 5 - 23.10.2024

Solving problems systematically

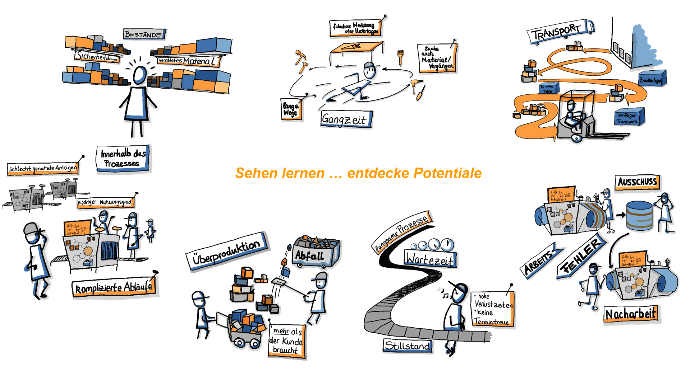

- Learning to see ... Recognizing potential (chalk circle exercise)

- Problem-solving cycles from problem identification to implementation

- Procedure and visualization when describing the problem

- Procedure and visualization for root cause analysis

- Procedure and visualization for finding solutions

- Exercises based on practical examples in the factory

Block 3 bei Rehm Thermal Systems GmbH

Tag 6 - 26.11.2024

Lean and TPM tools for optimizing processes

- Power set-up as a success factor

- Analyze value streams and optimize throughput times

- Visualize processes

- Lean in the office - what are the differences?

- Exercises in the factory

Tag 7 - 27.11.2024

Motivation and coaching in the team and sustainability in implementation

- Perception, analysis, handling and resolution of conflicts

- How to motivate participants in the workshop

- How to motivate participants in the workshop

- How to motivate participants in the workshop

- Coaching in dealing with conflicts

Each block includes method training and social skills training. In some cases, these are combined in exercises. The detailed planning of the individual day's content is geared towards the possibilities of practical exercises in the host factories. A precise agenda is agreed with the participants at the beginning of each block.

Implementation of your own practical project (optional):

All participants have the opportunity to carry out a practical project in their own company parallel to the training. If desired, you will be coached and have the opportunity to present the results to the team in an online presentation.