Tools & Services

Where production experts help each other

Lean

Wertstromanalyse - WSD

Lean method

The value stream analysis creates a transparent visualisation of the value creation steps in our processes. However, it also reveals where double handling, unnecessary effort and waste are hidden.

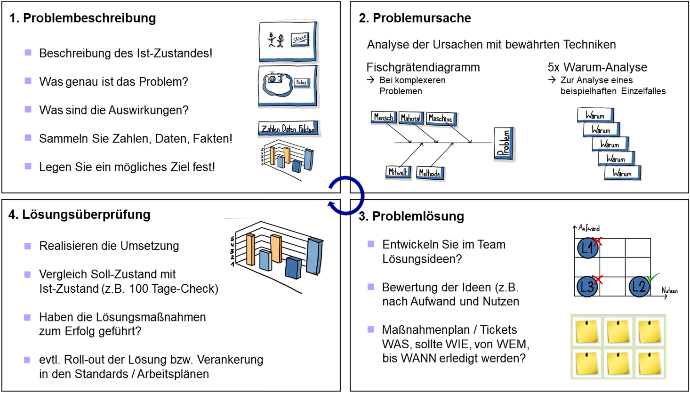

Die Q-plus Methode

Lean method

There are many systematic problem-solving methods (Q+, PDCA, A3, 8D, DMAIC, ...). The Q-Plus method is simple and, above all, lays the foundation for good solutions with a thorough problem description.

KPI und Office Scorecard

Lean method

In an "office scorecard", the purpose of the organisational unit is presented as a measurable criterion (success or performance indicator) and two or more influencing factors (driver variables or disturbance variables) on this success indicator are measured.

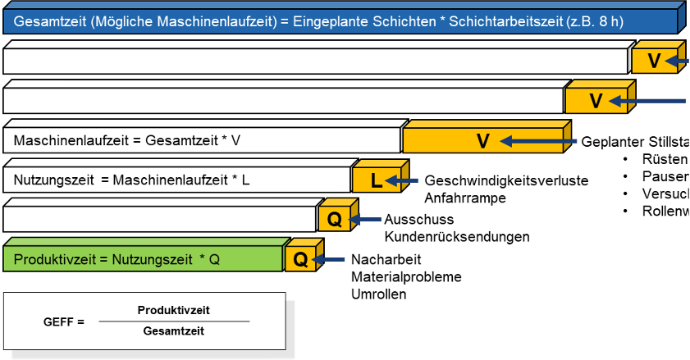

OEE-Optimierung

Lean method

The added value in our factory depends crucially on whether the systems are running and therefore on the OEE / GEFF.

Lean and TPM now aim to recognise all losses in the systems and reduce them step by step.

Sehen lernen - den 7 Verschwendungsarten auf der Spur

Lean method

Lean aims to avoid waste. To do this, we have to "learn to see" and discover the waste.

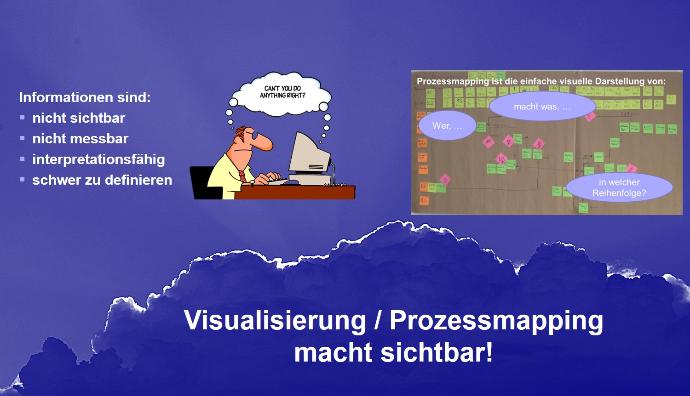

Prozessmapping im Office

Lean method

In contrast to production processes, office processes are almost invisible. This makes transparent visualisation all the more important for the team.

Works Quick Check

Lean Benchmarking

The works check is based on an assessment of success factors in 8 key areas. In the brief assessment, you can set a value from 1-10 yourself.

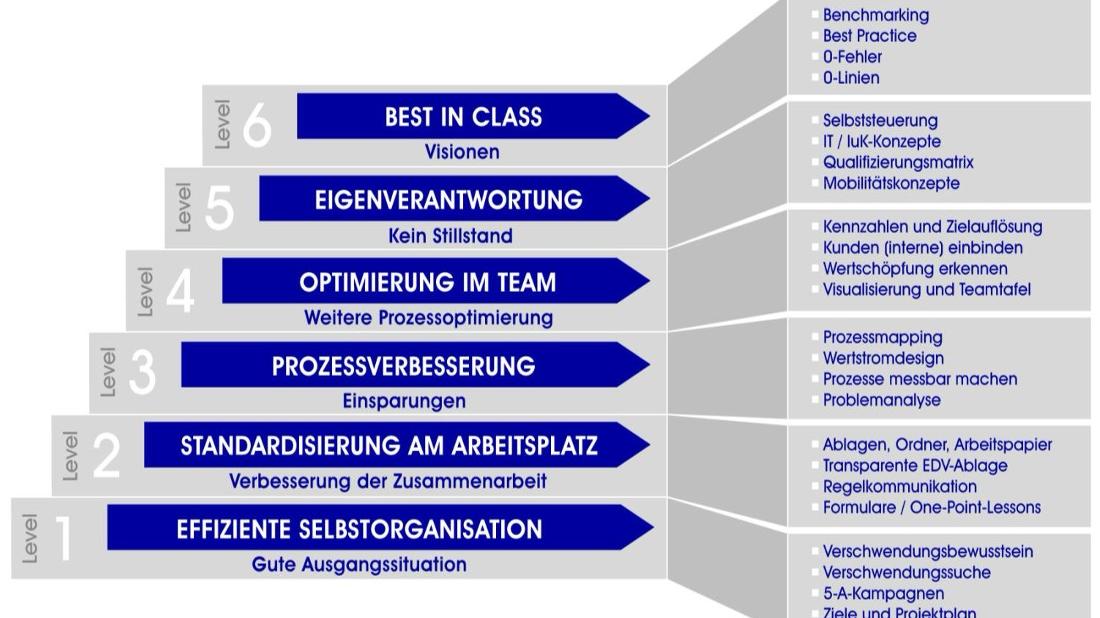

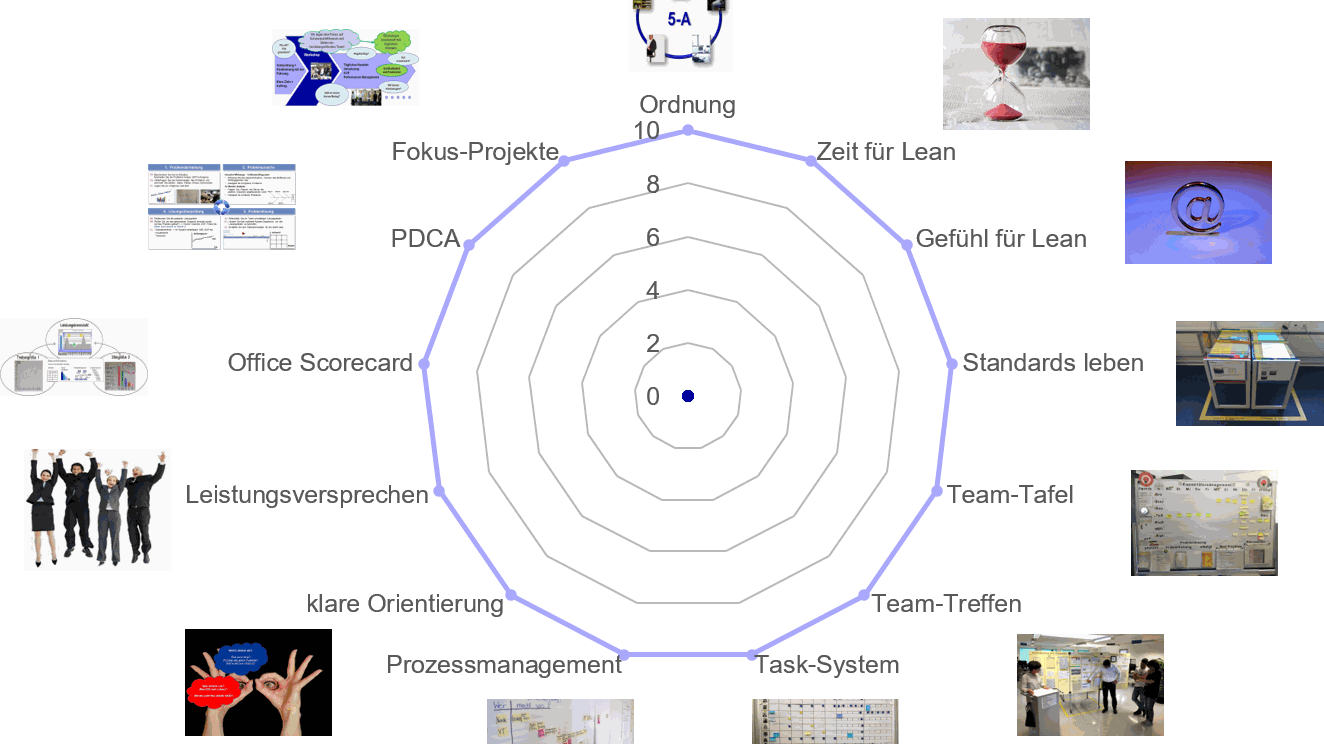

Office Excellence Check

Lean Benchmarking

Office Excellence offers a system for employee-orientated improvement of indirect processes. The corresponding tools are organised in levels so that the overall process remains understandable for those involved and implementation can be structured.

Office check - Lean basics

Lean Benchmarking

The Quick-Check Office - Lean Basics is designed for departments and teams and assesses how well they are on the way to office excellence and efficient work processes.

Office-Check - Work 4.0

Lean Benchmarking

The Office Check - Work 4.0 is intended for departments and teams and assesses how far they have come on the path to innovative, digital working structures.

10 workshop concepts for process improvements

Lean method

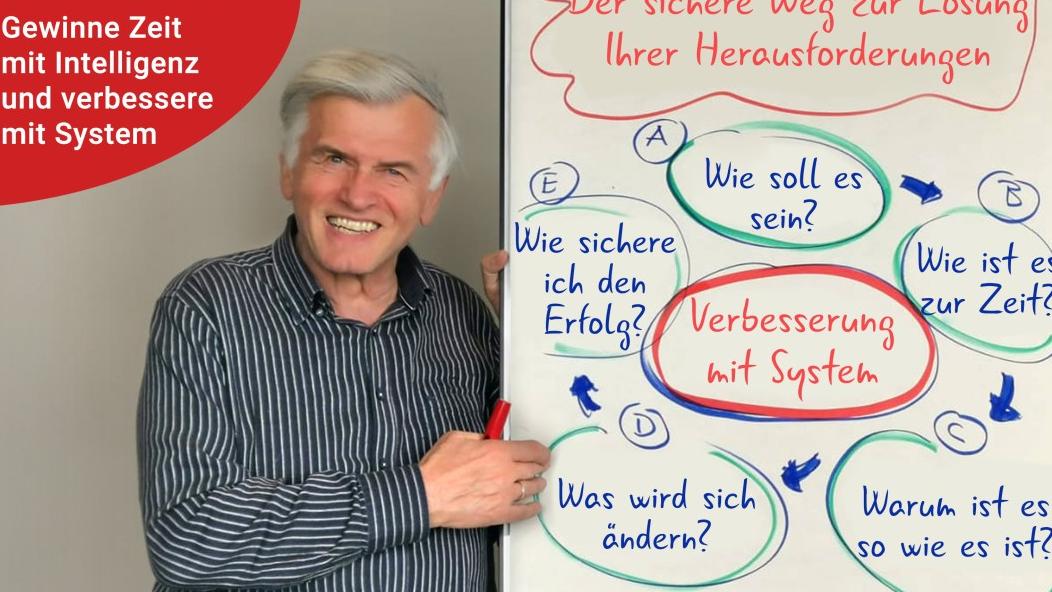

Robert Hierl is considered a master of continuous improvement. He has studied the culture of improvement in Japan and led it to success here in Germany. Now he shares his path to success.

Value stream mapping & process plan - The combination power('s)

Lean method

When people are faced with problems, it's good to have experts on hand.

If they find a solution, we quickly become reverent and think that these solutions will always help. More and more people want to jump on the bandwagon.

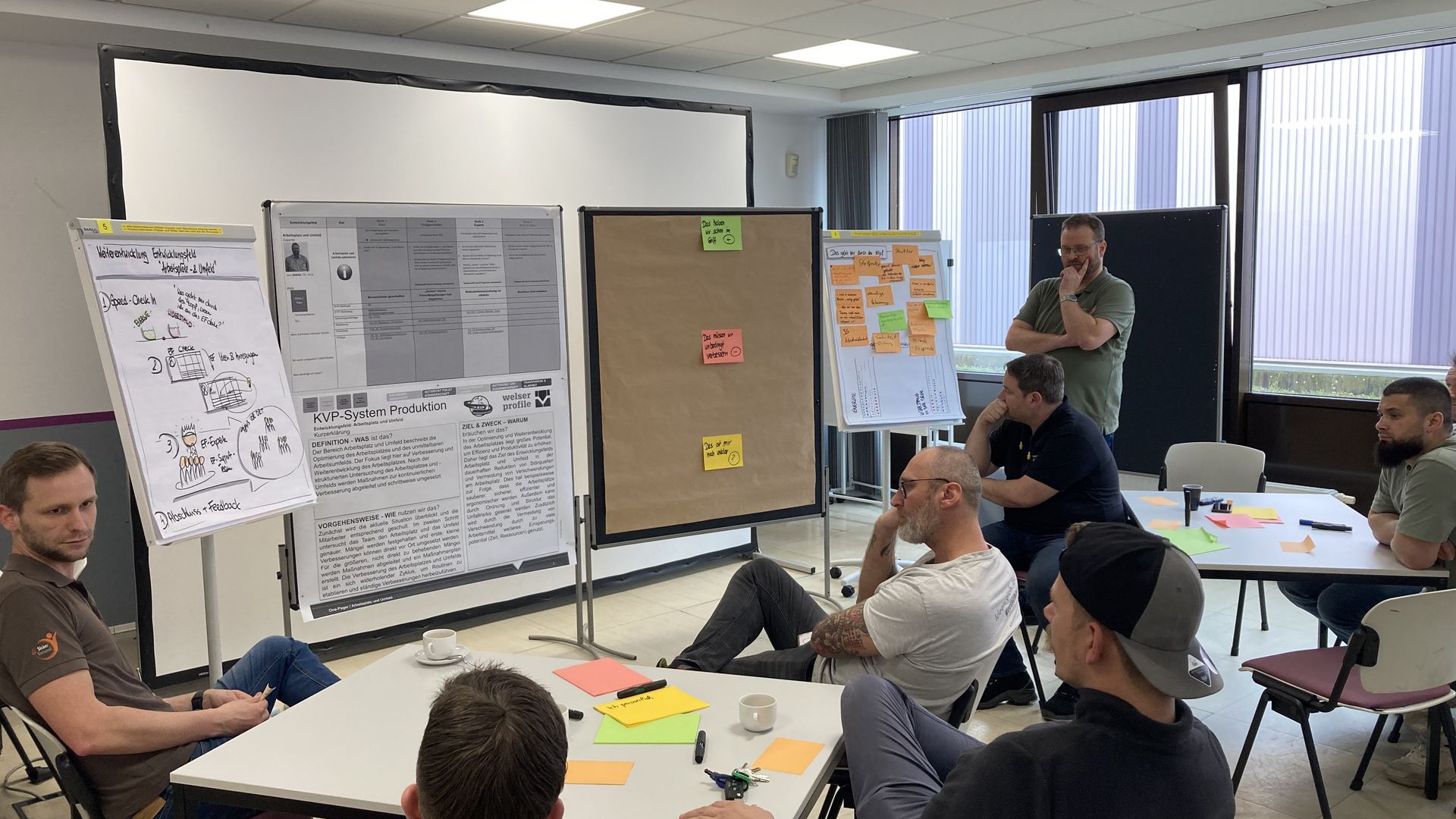

Agile Teams im Produktionsumfeld

Webinar

Die Welser Profile GmbH

setzt seit vielen Jahren innovative Organisationsformen und Lean um. Shopfloormanagement, Teamtafeln, KVP und Teamarbeit sind gelebte Praxis. Der nächste Schritt ist, agile Methoden und Prinzipien auch in den Produktionsprozessen zu nutzen.

LEAN BEST BASICS

Webinar

Lean ist eine Art zu arbeiten, die erfolgreich macht. Ein Handwerk, deren Methoden man erlernen kann, in erfahrenen Unternehmen erleben kann und jedes Unternehmen widerstandsfähiger in Krisen und Transformationen macht. Das Werk von ams Osram in Schwabmünchen ist ein lebendes Vorzeigebeispiel für Lean. Im Gespräch mit dem Werkleiter Ingo Hild und dem Operational Excellence Leader Dietmar Schäfer spreche ich über ihre bewegte Lean Reise.

Make LEAN simple again

Webinar

Sie kennen das. Wenn man sich neu mit einem Thema beschäftigt, will man alles darüber wissen. Mit der Zeit konzentriert man sich allerdings auf das Wesentliche. Genau so ist das auch beim Thema LEAN. Mit zwei ausgewiesenen Lean Experten aus zwei Konzernunternehmen spreche ich über Ihre jahrzehntelange Umsetzungserfahrung in Japan und Deutschland.

SIX SIGMA: Prozessverbesserung für Fortgeschrittene

Webinar

Wenn die Kunden mehr erwarten als die Prozesse leisten, kommen schnell Mathematik und Methode ins Spiel. Denn was man messen kann, lässt sich auch verbessern. Wo klassische Prozessoptimierungen bereits an die Grenzen stoßen, erreicht man mit Six Sigma und der DMAIC-Methode immer noch zuverlässig sein Ziel.

Lean goes Digital – Der Booster für effiziente Kommunikation und Verbesserung am Shopfloor

Webinar

Lean Manager haben lange Zeit auf Papier und Bleistift gesetzt, wenn es um die Verbesserung Ihrer Prozesse ging. Aus gutem Grund. Denn nur so konnte die gemeinsame Verbesserungsarbeit am Shopfloor zur gelebten Kultur werden. Jetzt ist die Zeit allerdings reif für Lean 2.0. Denn die Digitalisierung schafft Transparenz auf Knopfdruck, spart Ressourcen bei der Datenaufnahme, ist stets aktuell und behält jeden Fehler und jede Verbesserungsaktivität im Gedächtnis.

Make LEAN simple again - Eine Handvoll Methoden reichen aus - 13. August 2025

Webinar

Sie kennen das. Wenn man sich neu mit einem Thema beschäftigt, will man alles darüber wissen. Mit der Zeit konzentriert man sich allerdings auf das Wesentliche. Genau so ist das auch beim Thema LEAN. Mit zwei ausgewiesenen Lean Experten aus zwei Konzernunternehmen spreche ich über Ihre jahrzehntelange Umsetzungserfahrung in Japan und Deutschland.

Lean-Erfolge lebendig halten

Webinar

Lean gilt weiterhin als Fundament für viele der neuen Herausforderungen in unseren Fabriken! Aber wie gelingt es, einmal erreichte Lean-Erfolge auch nachhaltig zu etablieren. Und wie gelingt es, neue und junge Mitarbeiter an die bewährten Methoden heranzuführen? Wir sprechen mit Jürgen Schoch, Lean-Experte bei Wieland, über den Aufbau eines lebendigen Netzwerks von Lean-Paten, Multiplikatoren und Praxis-Experten

Green

Farbe bekennen beim Klimaschutz – Warum nichts tun unnötig teuer wird

Net Zero Best Practice

Unternehmen müssen Farbe bekennen beim Klimaschutz. Denn nichts tun wird unnötig teuer. Dabei zeigt Bosch als erster CO₂-neutraler Industriekonzern der Welt, dass Pflichten und Chancen eng beieinander liegen. Bosch spart heute in seinen Werken einerseits über 40% Energiekosten pro Teil ein und punktet zusätzlich mit seiner Klimastrategie bei CDP-Lieferantenratings seiner Kunden, bei Zinsverhandlungen mit Banken und durch ein effektives CSRD-Nachhaltigkeits-Reporting.

New paths to a cost-effective energy supply

Net Zero Best Practice

Professor Alexander Sauer from Fraunhofer IPA counters with concepts such as the ultra-efficient factory, with bio-intelligent value chains, but also with tools that are already available today that not only make our energy systems CO2-neutral, but also cost-efficient in order to be prepared for volatile and local energy generation.

Climate-positive production - how does it work?

Net Zero Best Practice

Climate-neutral production is no longer a vision of the future for the medium-sized company elobau, but has been a reality since 2010. But the climate pioneer from Leutkirch wanted even more and, in addition to its own emissions (Scope 1 & 2), also recorded all emissions that occur along the value chain of its own products (Scope 3).

What makes an energy self-sufficient plant tick?

Net Zero Best Practice

The best example of this is the Allgäu-based plant manufacturer Alois Müller with its largest, almost energy self-sufficient production and office building in the world. In fact, the daily weather forecast at the start of work determines work scheduling and machine utilisation. This is particularly true for energy-intensive processes.

Green products and black numbers

Net Zero Best Practice

The German market leader for household cleaners is serious. With its “Frosch” products, the Mainz-based company Werner & Mertz continues to set new standards for a functioning circular economy that go far beyond its own industry.

- Packaging made from 100% recycled plastic

- Environmentally friendly and biodegradable ingredients

- High-quality upcycling instead of inferior downcycling

- Innovations from the yellow bag material

Digital

The digital check for your factory

Industry 4.0 Benchmarking

Put your production processes to the test. Are you fit for Industry 4.0?

Benefit from immediate feedback with detailed benchmark comparisons and tips for self-help

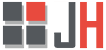

How the smart factory succeeds safely

Industrie 4.0 Reifegrad

Production has no future without digitalisation. Johann Hofmann, Germany's No. 1 Industry 4.0 expert, condenses his experience into a 30-minute webinar and uses five "natural laws of digitalisation" to explain how the smart factory can be a success

AI in production - stumbling blocks, tips & tricks

Webinar

Data doesn't produce anything, but it can be used to improve production. Approaches such as ChatGPT have virtually triggered an AI hype in the industry. "General world knowledge" becomes available at the touch of a button through such "large language models".

Digitisation of machines in three minutes

Getting started with digitalisation

Discover a technology that can digitise machines within three minutes using an IP68 smartphone. Learn more about the set-up process, including the placement of sensors, and see how the smartphone can switch on, heat up and monitor a coffee machine.

Die digitale Fabrik für jedermann

Webinar

Erfahrung ist durch nichts zu ersetzen. Und davon hat Bosch bei der Digitalisierung seiner rund 400 Fabriken reichlich gesammelt. So setzt Bosch heute Softwaretools ein, die eine Digitalisierung quasi als Plug&Play-Lösung möglich machen.

Die besten KI-Anwendungen für die Fabrik

Webinar

Moderne Fabriken produzieren immer mehr Daten. Nur ein Bruchteil davon wird allerdings von MES- und ERP-Systemen für die tatsächliche Steuerung der Fabrik verwendet. Und der Rest? Meist gehen die Daten verloren oder wandern ungenutzt in die Cloud. Gemeinsam mit Industrie 4.0 Pionier Johann Hofmann und dem Data Analysten Dr. André Kempe diskutieren wir praxisnahe KI-Use Cases.

Next Level in der Intralogistik

Webinar

VW Nutzfahrzeuge ist im Werk Hannover der Durchbruch gelungen, unterschiedlichste manuelle Verkehre durch vollautomatische Transportsysteme standardisiert zu orchestrieren. Hierzu errechnet eine Steuerungssoftware in Echtzeit die jeweils besten Versorgungslösungen, um den Hardwareeinsatz zu minimieren und die Versorgungssicherheit zu maximieren.

Der Boxenstopp in der Produktion

Webinar

Störungen sind der Feind der Produktion. Diese zu verhindern bzw. schnell und nachhaltig zu beseitigen entscheidet über Sieg oder Niederlage, - ähnlich wie der Boxenstopp in der Formel 1. Wie sieht er also aus, der moderne Boxenstopp in der Produktion? Mit dem „Maschinenflüsterer“ Heinz-Joachim Schulte spreche ich über präventive Wartungsstrategien, systematische Fehlersuche und nachhaltige OEE-Verbesserung.

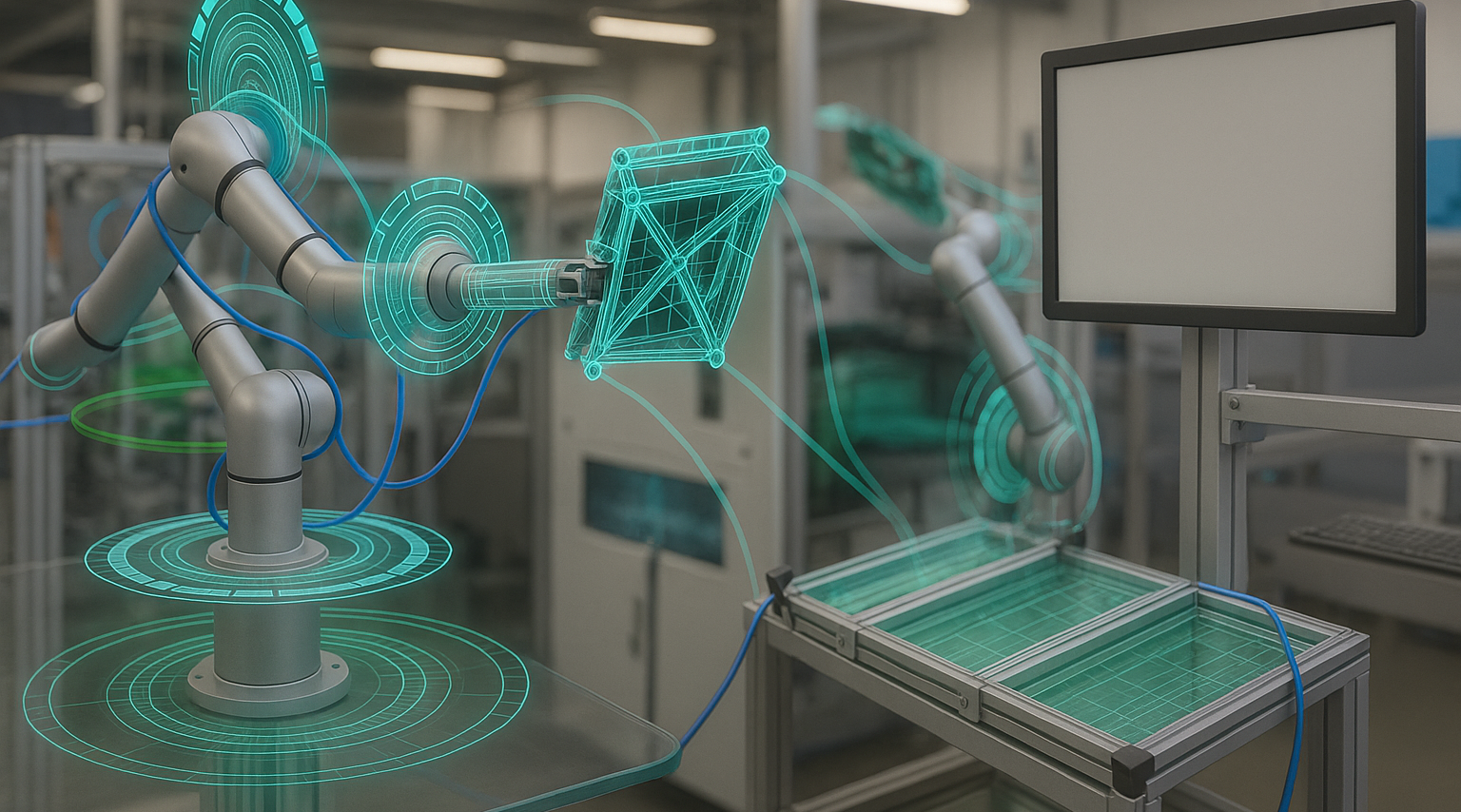

Smart Automatisieren Optimieren vor Investieren

Webinar

Mit den Lean- und Automatisierungsspezialisten

Achim Kelbel

und Gerold Henrichsen diskutiere ich getreu dem Motto „Reduce to the Max“ über den richtigen Weg der

Prozessoptimierung

und

Automatisierung

. Dabei werden wir auf manuelle Tätigkeiten in Montagen und im Handling von Werkstücken und Werkstückträgern fokussieren.

Die besten KI-Anwendungen für die smarte Fabrik

Webinar

Moderne Fabriken produzieren immer mehr Daten. Nur ein Bruchteil davon wird allerdings von MES- und ERP-Systemen für die tatsächliche Steuerung der Fabrik verwendet. Und der Rest? Ohne digitalen Zwilling gehen die Daten meist verloren oder wandern ungenutzt in die Cloud. Gemeinsam mit Industrie 4.0 Pionier Johann Hofmann und dem Data Analysten Dr. André Kempe diskutieren wir den Weg zur smarten Fabrik mit praxisnahen KI-Use Cases zur Ausschusserkennung, vorausschauenden Wartung und zur Absatzvorhersage.

Fertigungsprozesse smart automatisieren: Optimieren vor investieren.

Webinar

Die Industrie setzt auf Automatisierung und Digitalisierung. Doch eine solche „Produktivität auf Knopfdruck“ kann teuer werden und könnte bestenfalls sogar vermieden werden. Denn das 1x1 der Prozessoptimierung sagt: Vermeiden – Vereinfachen – Integrieren – Automatisieren. Und zwar in dieser Schrittfolge. Mit den Lean- und Automatisierungsspezialisten Achim Kelbel und Gerold Henrichsen diskutiere ich getreu dem Motto „Reduce to the Max“ über den richtigen Weg der Prozessoptimierung und Automatisierung. Im Fokus stehen dabei Leichtbauroboter, die sich als Lowcost-Automatisierung für manuelle Montage- und Handlingsprozesse zunehmend durchsetzen.